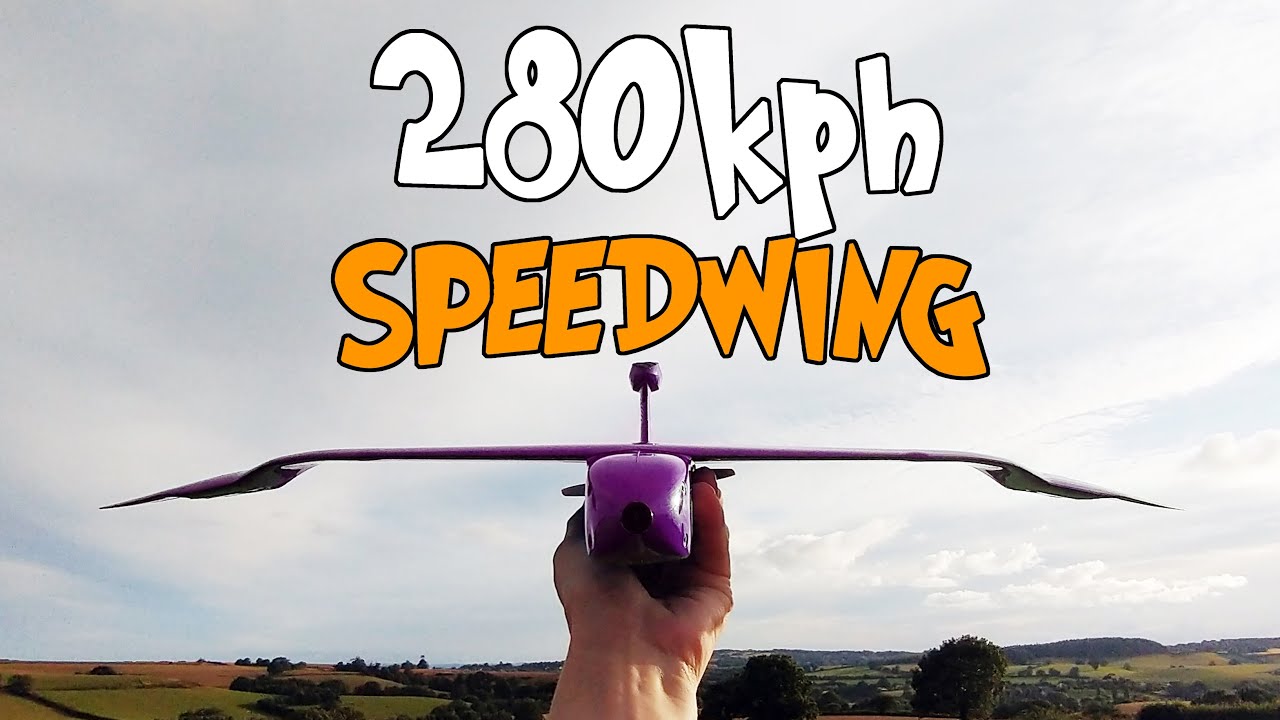

You’re about to embark on an exciting exploration of the Purrz 75 FPV drone, collaborated with Flypers, a noteworthy German company. This drone, named the Pro 75, boasts the ability to soar at speeds exceeding 280 kph, capturing the interest of drone enthusiasts with its distinctive design and impressive performance potential. Highlighting its intriguing package contents, you’ll discover thoughtfully designed accessory bundles, a single-piece wing, and a fuselage made from reinforced materials that ensure both durability and agility.

As you venture into the technical aspects of this incredible model, the ingenuity of its construction is apparent, from the innovative wing design to the sophisticated internal components. The assembly process poses a series of intricate challenges, making it an engaging endeavor for those who appreciate drone craftsmanship. The final build promises not only speed and agility but a unique flight experience, underscoring the Pro 75’s visually striking appearance and high-performance capabilities. Despite a few setbacks, the story unfolds to reveal the Pro 75’s remarkable potential for exhilarating drone adventures.

Collaborator and Project Overview

Introduction to Flypers: The German Company Partnering in the Review

Imagine the thrill of teaming up with an innovative German company like Flypers, which has made waves in the world of drone technology. Flypers reached out with an exciting offer to review their latest creation, the Pro 75 FPV drone, and you couldn’t resist the temptation. Known for their cutting-edge designs and technology, Flypers has become synonymous with innovation in the aircraft industry. Their partnership brings a promise of accessing the Pro 75, a drone that claims to push the boundaries of speed and performance.

Overview of the Pro 75 FPV Drone: Speed and Design

Now, let’s talk about the star of the show — the Pro 75 FPV drone. This model is not your average drone; it’s a masterpiece crafted for speed enthusiasts. With claimed speeds exceeding 280 kph, the Pro 75 is designed to make even the most seasoned drone enthusiasts sit up and take notice. Its sleek design and aerodynamic profile are inspired by high-speed aircraft, setting it apart in the FPV drone community. The Pro 75 FPV is a drone that promises a thrilling experience, blending speed, agility, and innovative design.

Aircraft Packaging and Components

Inside the Box: A Look at the Components

Opening the Pro 75’s packaging feels like unwrapping a gift filled with potential. Inside the sturdy box, you find everything meticulously organized, waiting to be assembled into a high-speed marvel. The main components include the single-piece wing and the fuselage made from glass-reinforced plastic, providing the necessary durability without sacrificing weight. Alongside these primary structures, you discover two accessory bundles filled with essential items for assembly, making it clear that Flypers thought of everything to ensure a smooth building process.

Accessory Bundles: Bungee Cord, 3D-Printed Parts, and More

The accessory bundles are treasure troves in their own right, adding value to your drone assembly experience. One bundle includes a bungee cord, vital for the successful launch of this high-speed aircraft. The other contains an assortment of 3D-printed parts, metal pieces, screws, and propellers — all the components you need to finalize your build. These thoughtful inclusions ensure you have all the tools necessary to maximize the Pro 75’s potential.

Materials Used: Glass-Reinforced Plastic Construction

Delving deeper into the Pro 75’s construction, you will appreciate Flypers’ choice of materials. The glass-reinforced plastic, essentially a fiberglass with a plastic coating, offers the perfect balance between strength and lightness. This material is pivotal in achieving the drone’s high speeds and aerodynamic efficiency. It’s a testament to Flypers’ commitment to quality and performance, ensuring that every flight is as thrilling as the last.

Design Features of the Pro 75

Nose and Fuselage: Housing the FPV Camera and Antenna

As you examine the design of the Pro 75, you notice the thoughtful integration of the FPV camera and antenna within the nose and fuselage. The nose features a dedicated space for the camera, allowing for optimal viewing angles during flights. The fuselage, on the other hand, houses not only the motor mount but also the FPV antenna, ensuring minimal interference and maximum performance. This design not only enhances the drone’s functionality but also maintains its sleek, aerodynamic profile.

Innovative Wing Design: Inspired by Fast Fighter Jets

Taking your inspection further, you can’t help but admire the innovative wing design. Drawing inspiration from fast fighter jets, the wings feature swept-back profiles and anhedral tips, optimizing the drone’s speed and agility. This incredible attention to detail reflects Flypers’ ambition to deliver a drone that captures the essence of speed and control in the air. The internal servo linkages also contribute to reducing drag, a clever engineering choice that further pushes the Pro 75’s performance boundaries.

Construction Details: Wooden Frame and Carbon Spars

One of the most intriguing aspects of the Pro 75 is its construction. The wing is built around a sturdy wooden frame complemented by carbon spars, which not only provide strength and durability but also enhance the drone’s agility. This construction choice demonstrates an impeccable blend of materials, combining the stability of wood with the cutting-edge properties of carbon, resulting in a high-performance aircraft that delivers on its promise of speed and maneuverability.

Building Complexity and Challenges

Space Limitations in the Fuselage: A Tight Fit

Embarking on the construction of the Pro 75, you quickly realize the challenges posed by space limitations within the fuselage. Every component needs to be carefully positioned, turning your assembly process into a precise exercise in spatial management. This tight fit requires thoughtful planning and execution, ensuring that each part is securely placed without sacrificing functionality or efficiency.

Difficult Installation in Wings: Servos and Linkages

As you move on to the wings, you encounter another set of challenges, primarily with the installation of servos and linkages. These components are crucial for the drone’s control and performance, yet their installation proves to be a meticulous task. The unique design of the wing, while innovative, complicates the process, requiring patience and precision to ensure everything fits and functions as intended.

Overcoming Hurdles in Assembly: A Test of Skills

Despite these hurdles, the assembly of the Pro 75 becomes a rewarding journey, testing and enhancing your skills as a builder. Each challenge overcome is a testament to your dedication and passion for high-performance drones. The satisfaction of seeing the completed aircraft ready for flight is unparalleled, and it’s here that you truly appreciate the intricate design and engineering of the Pro 75.

Technical Assembly Process

Utilizing the Metek F411 Wing Flight Controller

Incorporating the Metek F411 wing flight controller is a critical step in the Pro 75’s technical assembly. Soldering pin headers onto the board allows for easy attachment of external components like servos and GPS, streamlining the process and minimizing future soldering requirements. This setup ensures that your drone is equipped for efficient performance and seamless control during flights.

Installation of ESC, Motor, and VTX: Key Steps

Next, you focus on installing the ESC, motor, and VTX — key components that power and control the Pro 75. The Cloud Phoenix 50 Amp ESC, along with the IFlight Xing 2306 2450 KV motor, is soldered and securely integrated into the drone’s framework. Each connection is carefully made to ensure reliable power distribution and responsiveness. The TBS Unify Pro Race 2 VTX is also installed with precision, contributing to the drone’s robust performance capabilities.

Secure and Methodical Component Placement

The placement of each component within the Pro 75 is not just about functionality but also about creating a cohesive and efficient system. Securing each part methodically ensures optimal weight distribution and balance, essential for achieving the high speeds and agility that the Pro 75 is designed for. This process brings a sense of completion and readiness to the aircraft, preparing it for its maiden flight.

Integrating Electrical Components

Soldering and Attachment Processes Explained

The integration of electrical components in the Pro 75 is an exercise in precision and care. Each soldering and attachment process is carefully executed to ensure strong and stable connections. By extending wires where necessary and using high-quality connectors, you create a reliable network of components that work seamlessly together, enhancing the drone’s overall performance and reliability.

Running the Wires: Challenges and Solutions

Routing wires through the Pro 75 presents its own set of challenges, especially given the compact design and intricate construction. Thoughtful planning and innovative solutions are required to navigate these challenges, using tools like tethered hooks to guide wires through tight spaces. This stage demands patience and foresight, ensuring that all components remain accessible and operational.

Efficient Component Connections: A Step-by-Step Guide

Achieving efficient component connections in the Pro 75 involves a step-by-step approach. Starting with the most complex connections and moving towards simpler tasks ensures that each component is installed systematically and without oversight. This methodical approach minimizes errors and ensures that every part of the drone functions as expected, ready to deliver top performance.

Installation of FPV Camera and GPS Unit

RunCam Phoenix 2: Mounting at the Nose

Mounting the RunCam Phoenix 2 at the nose of the Pro 75 is an essential step in creating an immersive FPV experience. Carefully extending the camera’s wiring and using a 3D-printed mount, you secure it in place, utilizing the best possible viewing angles. This setup ensures that you capture every thrilling moment of the drone’s flight in crisp, clear visuals.

Extending Wires and Ensuring Secure Fixation

Ensuring that the wiring for your FPV camera and GPS unit is properly extended and securely fixed is crucial. Using structured cabling methods and securing each wire in place, you minimize vibrations and potential disruptions during flight. This care in wiring not only enhances reliability but also contributes to the streamlined aesthetic of the Pro 75.

GPS Integration with Midtech Maq58a3: Location and Connection

The integration of the Midtech Maq58a3 GPS unit is pivotal for accurate positioning and navigation. You install it at the front of the fuselage, extending its wires and connecting it seamlessly to the flight controller. This setup ensures that the Pro 75 has precise positioning capabilities, contributing to its agility and performance in the air.

Wing Assembly and Servo Challenges

Mind the Wings: Precise Servo Installation

Installing servos in the Pro 75’s wings requires attention to detail and precision. Modifying the housings to fit your chosen servos and securing them in place, you ensure they function correctly and contribute to the drone’s responsive control. This meticulous process is vital for the Pro 75’s overall performance and success during flights.

Challenges in Routing Wires Through Wings

Routing wires through the wings of the Pro 75 presents a series of challenges, demanding strategic planning and creative solutions. Ensuring they reach their destinations without being snagged or damaged requires patience and ingenuity, utilizing tools like tethered hooks to guide them through. Each successful routing leads you closer to completing your high-speed drone.

Finalizing Wing Assembly: Connecting Linkages

The final stage of wing assembly involves connecting the linkages with precision and care. Properly aligned and secured, these linkages are crucial for the drone’s control and maneuverability. Completing this step with attention to detail ensures that the Pro 75 is ready for its high-speed flights, delivering the agility and performance it promises.

Testing and Performance Analysis

Initial Launch Failures: Learning from Mistakes

The first launch of the Pro 75 may not go as planned, providing an opportunity to learn and adapt. Whether due to a bungee that fails to release or unexpected balance issues, these challenges offer valuable insights for future attempts. Each failure becomes a stepping stone towards achieving successful flights, refining your technique and setup.

Successful Flights: Speed Achievements

Once in the air, the Pro 75 showcases its impressive capabilities, reaching remarkable speeds and demonstrating its agility. Achieving a top speed of 240 kph may fall short of the claimed maximum, but it’s a testament to the drone’s potential. Each flight becomes a celebration of its design and your efforts, proving that the Pro 75 is a force to be reckoned with in the FPV drone world.

FPV Transmission Issues: Analyzing Outcomes

Despite the successful flights, FPV transmission issues can arise, providing further learning opportunities. Analyzing these challenges and implementing solutions, such as repositioning antennas or adjusting settings, helps improve the transmission quality. These adjustments ensure that future flights not only perform well but also deliver spectacular visuals from the drone’s eye view.

Conclusion

High Performance vs. Fragility: A Balance of Design

The Pro 75 offers an exhilarating mix of high performance and innovative design, but not without its limitations. Its lightweight fiberglass construction, while contributing to speed and agility, poses fragility concerns. Balancing these attributes is crucial to fully harnessing the drone’s potential without compromising its durability.

Potential Improvements for Durability

To enhance the Pro 75’s longevity, considering design improvements without sacrificing performance is essential. Reinforcing vulnerable areas, adjusting material choices, or incorporating additional protective elements can help address fragility concerns, ensuring that the Pro 75 continues to deliver high-performance flights over time.

Overall Verdict: A High-Speed Adventure with Limitations

In conclusion, the Pro 75 FPV drone delivers an impressive high-speed adventure with its unique design and performance capabilities. While challenges in building and fragility pose limitations, the thrill of flying at remarkable speeds makes the Pro 75 a captivating addition to the world of high-performance drones. With potential improvements in durability, the Pro 75 could become not just a fast drone but also a resilient companion for adrenaline-fueled adventures in the sky.