Understanding how to estimate the thrust of your drone is an essential part of selecting the right components such as motors, props, and batteries. In “How to Estimate Thrust of Your Drone,” you’ll learn about three effective methods to gauge the thrust and current draw of your drone’s drivetrain. These techniques are crucial for ensuring that your drone can achieve the desired performance before you even begin assembly. With these insights, you’ll be better prepared to make informed decisions for your drone-building endeavors.

The video explains three approaches: bench testing, using online data, and relying on manufacturer’s thrust tables. Each method has its perks and drawbacks. Bench testing delivers accurate data but requires you to have the hardware upfront. The other two options offer convenience, with online data allowing comparisons without initial purchases and manufacturer tables providing easy-to-access info. By understanding these methods, you’ll be equipped to choose the best approach that fits your needs and resources.

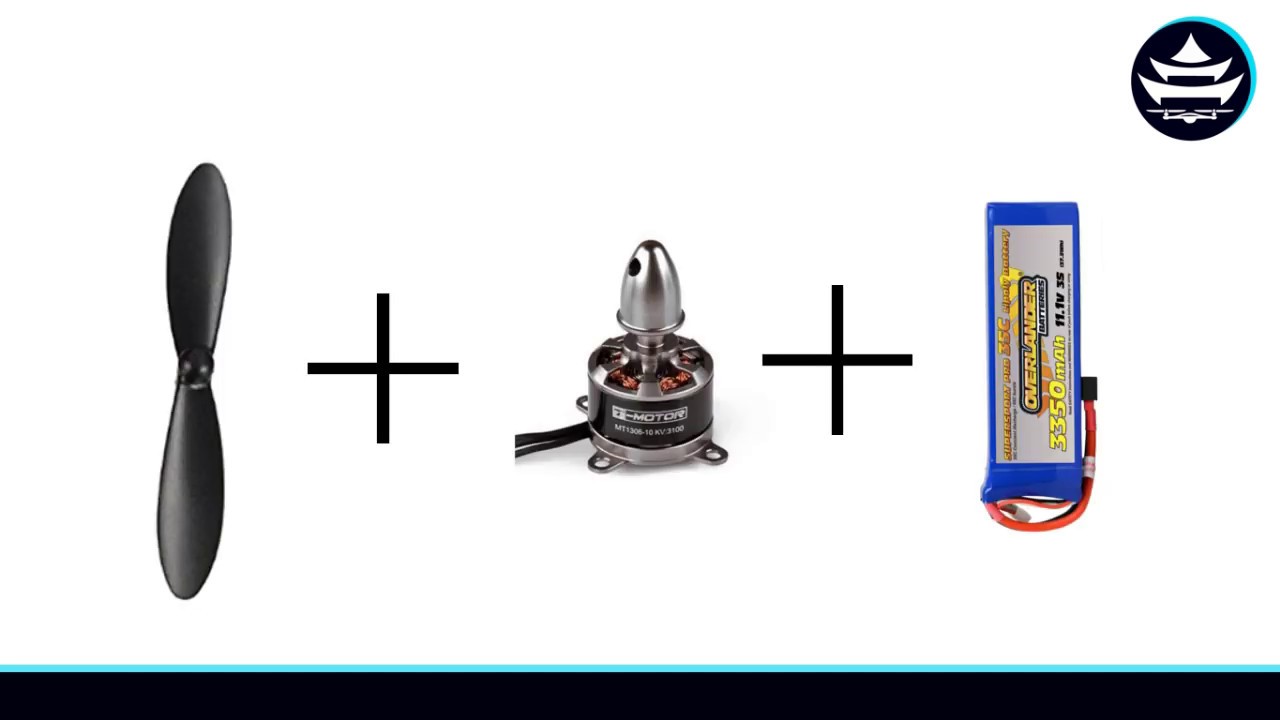

Estimating thrust is an essential step to ensure you choose the correct parts for a drone you plan to build.

By now, in the design process, you should have selected motors, props, and a lipo. Now you need to assess what thrust your chosen parts will produce.

If you’re interested in a comprehensive 6-hour curriculum to kickstart your drone engineering journey, check out this course!

https://dojofordrones.com/how-to-buil…

Understanding the Importance of Thrust Estimation

When embarking on the journey of building a drone, one of the critical factors you’ll encounter is the need for accurate thrust estimation. It’s an essential step that sets the foundation for your entire project.

Key Role in Selecting Drone Components

Thrust estimation plays a pivotal role in selecting appropriate drone components such as motors, propellers, and batteries. Understanding how much thrust your setup will generate allows you to make informed decisions about the components you choose. Essentially, these decisions will affect the overall drone design, performance, and capability. By accurately estimating thrust, you ensure that every component complements one another, leading to a well-balanced and efficient system.

Impact on Drone Performance and Efficiency

Thrust is directly linked to your drone’s performance and efficiency. If you underestimate the thrust capability, your drone might struggle to lift off or maneuver as intended. On the other hand, overestimating thrust can result in unnecessary energy consumption and reduced flight time. Knowing the right amount of thrust helps streamline efficiency—ensuring that the drone uses just the right amount of power to perform its tasks effectively.

Influence on Motor, Propeller, and Battery Choices

Motor, propeller, and battery choices are heavily influenced by thrust estimation. Each of these components must be carefully selected to provide the optimal thrust-to-weight ratio that matches your drone’s intended purpose. Motors need to deliver the required torque; propellers must be of the right size and pitch; batteries must have the appropriate voltage and capacity. Incorrect choices can lead to performance hiccups or even component failure. Therefore, precise thrust estimation helps in choosing the best components for a robust setup.

Key Components Involved in Thrust Generation

Thrust generation is a complex interplay of various factors, including motors, propellers, and batteries.

Motors: Specifications and Types

Motors are the heart of your drone’s thrust generation. They come in different specifications and types, such as brushed and brushless motors. The key specifications to consider include the motor’s size, kv rating (which indicates the motor’s speed constant), and its torque capability. Selecting the right motor requires an understanding of how much thrust it can generate at different power inputs, ensuring that it suits your drone’s weight and flight requirements.

Propellers: Size and Pitch Considerations

Propellers are another vital component in the thrust equation. The size and pitch of a propeller significantly affect how much thrust is produced. Larger propellers can produce more lift but may require more power. The pitch, which refers to the angle of the blades, affects the speed at which the air is pushed downward. It’s crucial to balance size and pitch to match your motor’s capabilities and your battery’s power output.

Batteries: Voltage and Capacity Relevance

The battery powers your drone, influencing how much thrust can be sustained. Voltage and capacity are the two main parameters to consider. A higher voltage battery can deliver more power, meaning greater thrust, while capacity determines how long your drone can sustain that thrust. Matching the battery to your motor and propeller setup is crucial for balanced performance.

Method 1: Bench Testing

Bench testing is a hands-on approach to determining thrust capabilities by physically measuring the thrust with a scale.

Setting up a Physical Test Environment

Setting up a test environment involves securely mounting your motor and propeller setup, connecting it to the intended battery, and ensuring that all safety measures are in place. The setup should be stable to avoid accidents, and a digital scale is typically used to measure thrust as the motor runs at various speeds.

Measuring Thrust Using a Scale

In bench testing, a digital scale under the motor measures the thrust generated when the propeller spins. This allows for real-time and accurate assessments. As you throttle up, the scale reading will give you a direct measure of the thrust produced at different power levels.

Pros: Reliable Data Collection

Bench testing provides reliable and empirically derived data specific to your setup. This real-world measurement gives confidence in the values you collect, allowing you to understand the exact performance of your selected components.

Cons: Requires Pre-Purchase of Components and Is Time-Consuming

The primary downside of bench testing is that it requires you to purchase the components upfront. Additionally, setting up and conducting the test can be time-consuming, especially if you’re trying to test multiple configurations.

Method 2: Using Online Data

This method involves leveraging existing data from similar setups found online.

Locating Relevant Test Results for Similar Setups

Many hobbyists and professionals share their test results online. You can locate relevant data by searching forums, blogs, and video tutorials that align closely with your intended setup.

Averaging Data for a More Accurate Estimate

Once you’ve gathered test results from various sources, you can average these to get a more accurate estimate of the thrust for your setup. This process helps to smooth out discrepancies or outliers that might skew individual results.

Pros: Avoids Early Component Purchase; Useful If Manufacturer Data Is Unavailable

Using online data avoids the need for early component purchases, which can be beneficial for preliminary estimations. It is also particularly useful if specific manufacturer data is unavailable, giving you a basis to move forward with your project planning.

Cons: Risk of Inaccuracies in Others’ Methodologies

The major downside is the potential for inaccuracies due to different testing methodologies and conditions. Since you rely on third-party data, discrepancies could mislead your estimates.

Method 3: Using Manufacturer’s Thrust Tables

Many manufacturers provide thrust tables for their motors, which is a valuable resource.

Accessing Thrust Tables Specific to Your Motor Setup

Manufacturers test their motors with a variety of propeller and battery combinations to produce thrust tables. Accessing these tables is typically as simple as visiting the manufacturer’s website or contacting their support for the data.

Interpreting the Data for Real-World Application

Interpreting thrust tables requires consideration of the specific conditions under which tests were conducted. Adjust the expectations by factoring in your own drone’s design and environment to apply these estimates in your build.

Pros: Convenient and Tailored to Specific Motors

Thrust tables offer a convenient method to understand what your motor can achieve under set conditions without conducting the tests yourself. It’s tailored and specific, often providing data for a range of configurations.

Cons: Potential Differences in Real-World Performance

While convenient, thrust tables may not perfectly reflect real-world performance due to differences in environmental conditions and additional system integrations.

Comparing the Three Methods

Bench Testing: Most Reliable but Least Convenient

Bench testing is the gold standard for precision, offering the most reliable data for your exact configuration, though requiring more effort and resources upfront.

Online Data: Best for Preliminary Estimations Without Component Purchases

Consulting online data is an excellent way to do preliminary checks without purchasing components, though it comes with accuracy risks.

Manufacturer’s Tables: Ideal Balance of Convenience and Reliability

Manufacturer’s thrust tables provide a nice balance, being both specific and convenient, though needing some adjustment for real-world application.

Choosing the Right Method for Your Project

Assessing the Level of Precision Needed

Choose your method based on how precise your thrust needs to be. High-stakes projects may necessitate bench testing, while exploratory or lower-budget ventures could lean on online data or manufacturer’s tables.

Considering Budget Constraints for Testing Equipment

Determine if your budget allows for the purchase of testing equipment or if online and manufacturer data suffice for your needs.

Evaluating the Availability of Online and Manufacturer Data

The availability of data might steer your method choice. If manufacturer data is readily available, it could simplify your selection process.

Practical Tips for Accurate Thrust Estimation

Ensuring Thorough Research on Component Specifications

Deeply understand the specifications of every component, from motors to batteries, as these details can greatly affect thrust calculations.

Verifying Credibility of Online Data Sources

When using online data, confirm the credibility of sources by checking their reputations and the consistency of their methodologies with standard practices.

Regularly Updating Calculations with Current Technology Trends

Technology evolves rapidly. Keep your calculations up-to-date by considering current trends and innovations in components.

Other Factors Influencing Drone Thrust

Environmental Conditions: Temperature, Altitude, and Humidity

Environmental factors such as temperature, altitude, and humidity can affect air density and, consequently, the thrust. These should be factored into your estimations.

Wear and Tear on Drone Components

Over time, wear and tear on components can reduce efficiency and thrust. Regular maintenance and checks can help mitigate this.

Drone Weight and Balance Considerations

The overall weight and balance of your drone will influence its performance and thrust needs. Ensure a balanced load for optimal operations.

Conclusion

Re-emphasizing the Importance of Accurate Thrust Estimation

Accurate thrust estimation is essential for any successful drone project, influencing performance, efficiency, and component choices.

Recap of the Three Primary Methods

We’ve explored three primary methods to estimate thrust: bench testing for accuracy, online data for preliminary estimations, and manufacturer’s thrust tables for a practical balance. Each method has its merits and downsides, and the right choice depends on your unique project circumstances.

Encouragement to Choose the Method That Best Fits Individual Project Needs

Ultimately, the best method is the one that aligns with your precision needs, budget, and available resources. Take the insights shared here to choose wisely and set your drone project on the path to success.