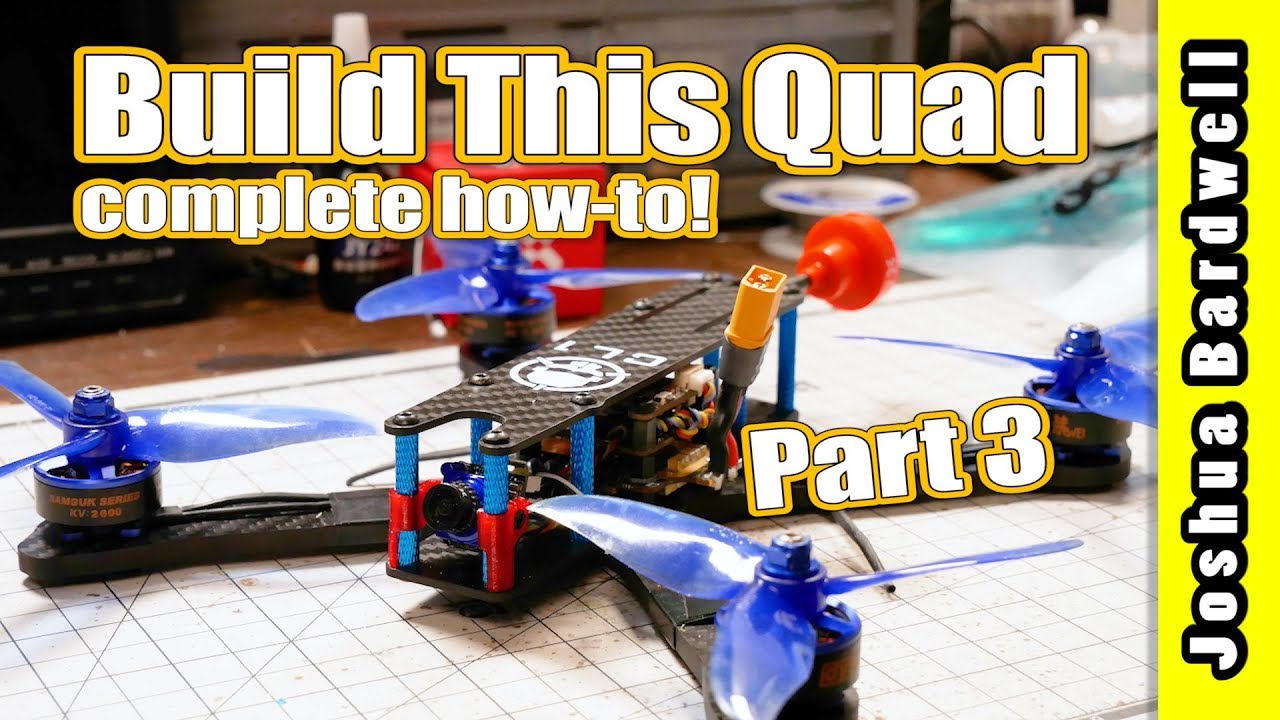

In the exciting “Learn To Build a Racing Drone – Part 3 – Install Motors and ESCs,” you’ll explore the crucial steps to mount your motors and ESCs onto your FPV quadcopter. Joshua Bardwell takes you through each detail, ensuring you grasp the installation process with ease and precision. Whether you’re starting this journey or catching up, there’s a wealth of resources available, including YouTube comments for questions and a vibrant Discord server for real-time support.

To get started on your build, you’ll require certain components and tools, which can be individually sourced if a kit isn’t available. As you work through this step-by-step guide, you’ll learn to attach your motors correctly, position ESCs efficiently, and even ensure your wires run smoothly along the drone’s arms. This hands-on experience will not only assemble your drone but will also empower you with practical knowledge for future projects.

Unsure of what to purchase? Take a look at THE ULTIMATE FPV SHOPPING LIST: https://www.fpvknowitall.com/ultimate…

SUPPORT ME ON PATREON at: http://bit.ly/2Ep5Sia

THIS IS MY FULL TIME JOB. Other ways you can support me are listed here: https://www.fpvknowitall.com/support-me/

I’ve designed a video series that guides even a complete beginner through the process of building an FPV quadcopter. Each video details every single step of building and configuring the drone, with the kind of detailed (yet straightforward) instructions I’m known for. If you have any questions, JB is keeping an eye on the YouTube comments, and there’s a Discord server chat channel for quicker assistance.

This video series goes beyond just providing you a completed quad ready to fly. It aims to teach you how to build a quad correctly, covering all the essential steps often missed.

The complete playlist for this build series is:

• Learn To Build A Racing Drone

Get this complete kit at Rotor Riot store:

https://rotorriot.com/products/bardwe…

Sadly, the Rotor Riot “kit” version of this build has been out of stock for some time, so I’m listing individual links to the parts. You’ll need to buy them separately if you want them.

1x Rotor Riot CL1 frame

Rotor Riot Store – http://bit.ly/2V1qab4

1x Holybro Kakute / Tekko / Atlatl stack

Banggood – http://bit.ly/2J98BOW

RaceDayQuads – http://bit.ly/2GGdhcs

Rotor Riot – http://bit.ly/2xaZtmt

GetFPV – http://bit.ly/2Ro58Nm

1x Foxeer Pagoda video antenna (or equivalent)

RaceDayQuads – http://bit.ly/2FYRjT4

Rotor Riot Store – http://bit.ly/2V6JKCT

Banggood – http://bit.ly/2V42e6U

4x DYS Samguk Wei 2207/2600 kv motors (buy a spare or two!)

Rotor Riot Store – http://bit.ly/2V6LlZp

RaceDayQuads – http://bit.ly/2V4llh1

Banggood – http://bit.ly/2V7uSUD

GetFPV – http://bit.ly/2vu1Orj

1x Foxeer Micro Arrow Pro FPV camera

Banggood – http://bit.ly/2vt84ja

RaceDayQuads – http://bit.ly/2WlIwQs

Rotor Riot – http://bit.ly/2UMyd6K

GetFPV – http://bit.ly/2IYo84i

Amazon – https://amzn.to/2tVxsgF

DYS Cyclone 5046×3 props (as many as you can manage)

Banggood – http://bit.ly/2VvS8v3

ReadyMadeRC – http://bit.ly/2V0HNb3

GetFPV – http://bit.ly/2V22jbb

Amazon – http://amzn.to/2EPVvV3

Pre-soldered XT60 power lead

Amazon – https://amzn.to/2WlJa0k

GetFPV – http://bit.ly/2VAbhvM

Rotor Riot – http://bit.ly/2V1BHac

RaceDayQuads – http://bit.ly/2V2uNll

Banggood – http://bit.ly/2GGk4CY

M3 Screw assortment (use 4mm or 5mm for the FC stack and 8mm for the motors).

RaceDayQuads – http://bit.ly/2GM3OjE

Rotor Riot Store – http://bit.ly/2GFUjTg

GetFPV – http://bit.ly/2UJrDxL

Amazon – https://amzn.to/2ZKhzZ2

Banggood – http://bit.ly/2GOP0kG

In addition, you will need to source the following:

Zip ties, 8″ length (to hold antennas and receiver)

Heat shrink, 3/32″ diameter, 2″ length, quantity 2 (4″ total length)

Double-sided tape for receiver, 1/2″ x 1″ — use double-sided foam tape, “servo tape”, Scotch Extreme Mounting Tape, or similar.

MANDATORY DISCLAIMER: I am a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for me to earn fees by linking to Amazon.com and affiliated sites.

Most or all links above are affiliate links, and I will receive compensation if you use them.

Tools and Materials Required

Building a racing drone is an exciting endeavor, and it all begins with gathering the necessary tools and materials. You’ll find this initial phase both crucial and rewarding as it sets the foundation for a smooth build process.

List of essential tools needed for installation

First, let’s look at the tools you absolutely need. You’ll require a quality hex driver set, commonly in sizes 2mm and 2.5mm, which are essential for fastening screws into your drone frame. A soldering iron is a must-have for creating solid connections between wires and electronic components. Tweezers are great for handling small parts, and a good pair of wire strippers will help you cleanly trim wires. A multimeter is invaluable for troubleshooting and verifying connections. Lastly, don’t forget to have a small Phillips screwdriver and some scissors handy.

Overview of required materials and components

Moving on to materials, start with a sturdy frame such as the Rotor Riot CL1 frame, designed for durability and performance. The powertrain will comprise four DYS Samguk Wei 2207/2600 kv motors, ideal for racing due to their powerful output. You’ll also need a set of DYS Cyclone 5046×3 propellers. Your flight controller, for example, a Holybro Kakute, will work with the Tekko ESCs to control the motors. A Foxeer Pagoda antenna and a Foxeer Micro Arrow Pro FPV camera provide your drone with the eyes and ears it needs to navigate. Don’t overlook smaller items such as zip ties, heat shrink tubing, double-sided tape, and an assortment of M3 screws.

Safety equipment and precautions

Safety is a priority. Ensure you’re equipped with protective eyewear to guard against any flying debris while working. A pair of anti-static wristbands can prevent damaging sensitive components with static electricity. Make sure your work area is well-ventilated, especially when soldering, to avoid inhaling any harmful fumes. Lastly, familiarize yourself with fire safety equipment—having a fire extinguisher nearby is a wise precaution when working with electrical components.

Understanding the Motor Specifications

A strong grasp of motor specifications will guide you in making the best decisions for your drone build, enhancing both its efficiency and performance.

Differences between motor types

Motors vary significantly based on design and function. Primarily, you’ll encounter brushed and brushless motors. Brushless motors, like the DYS Samguk Wei, are preferred for drone racing due to their efficiency, power, and durability. While brushed motors are simpler and cheaper, they wear out faster and are generally less reliable for high-performance builds.

Key performance factors of racing drone motors

When evaluating motors, several performance factors come into play. The kv rating, indicating revolutions per minute per volt, is crucial; higher kv ratings, like 2600 kv, mean faster speeds, which is often desirable in racing. Consider also the motor’s thrust-to-weight ratio, affecting how well your drone can maneuver. Efficiency, measured by how much power is converted into thrust, directly impacts flight time.

Choosing the right motor for your build

Select motors that align with your racing goals. High-thrust motors are excellent for aggressive, high-speed racing, while slightly lower-thrust motors might offer better flight efficiency for endurance racing. Ensure your chosen motor matches the other components, like the ESCs and battery, to prevent bottlenecking performance.

Preparing the Frame for Motor Installation

The groundwork for an efficient and well-balanced racing drone begins with correctly preparing your frame.

Aligning the frame for balanced weight distribution

Begin by laying out your components on the frame to understand how weight will be distributed. Balance is key in racing drones; thus, place heavier components, like the battery, centrally. This improves maneuverability and flight stability.

Marking motor mount positions

Identify the dedicated motor mounts on each arm of the frame. These typically have pre-drilled holes. Ensuring that these holes align properly with your motor’s mounting pattern is vital for stability. Use a marker to lightly outline these positions if needed.

Ensuring structural integrity before installation

Before installing motors, inspect the frame for any signs of damage or manufacturing defects. Tighten all screws and fasteners to secure connections, preventing unnecessary vibrations or loosening during flight.

Motor Installation Steps

With a prepared frame, you’re ready to mount the motors.

Securing motors to the frame

Position each motor on the pre-marked mount, ensuring the wires are oriented to minimize slack. Use the correct length screws to affix each motor securely, taking care not to overtighten and strip the mounting holes.

Tools required for motor mounting

You’ll need a 2.5mm hex driver in most cases. Ensure the screws you’re using are the correct length to avoid damaging motor windings.

Common mistakes and how to avoid them during installation

A common mistake is using screws that are too long, which can damage the motor internals. Double-check screw length and tighten evenly to prevent stress fractures. Another pitfall is orienting motor wires improperly, so plan the wire routing to avoid contact with spinning propellers.

Understanding Electronic Speed Controllers (ESCs)

The ESCs serve as the power regulators of your drone, converting signals from the flight controller into precise electrical power to the motors.

What are ESCs and their role in drones

Electronic Speed Controllers bridge the flight controller and motors. They take in low-voltage signals indicating required motor speed and adjust the electrical power flow to motors accordingly, enabling precision control over thrust and speed.

Key specifications to consider

Critical ESC specifications include current rating, referring to how much power the ESC can provide without overheating—typically, higher ratings are needed for more power-hungry motors. Also, consider the number of supported firmware, such as BlHeli, which allows for detailed configuration and calibration.

Popular ESC brands and models

Some reputable brands include Holybro and DYS, offering models like the Tekko series. These are recognized for their reliability and performance, providing consistent power delivery and integration with various flight controllers.

ESC Installation Preparation

A proper setup of your ESCs ensures efficient power distribution and communication across your drone.

Organizing wires for efficient setup

Before installing, neatly lay out all wires to prevent tangling. Group wires based on their destinations—power leads, signal wires, etc., making connections straightforward and serviceable.

Deciding on ESC location on the frame

Consider accessibility and cooling needs when positioning ESCs. Often, ESCs are mounted on or near motor arms, minimizing signal delay and keeping them within the prop wash for cooling.

Preparing the frame and environment for ESC installation

Clean all surfaces where ESCs will be placed to ensure strong adhesion. Use double-sided tape or other mounting adhesive as required. Organize your workstation to keep track of tools and components, maintaining a tidy workspace to minimize errors.

Wiring ESCs to Motors

Proper wiring is crucial for drone responsiveness and safety.

Step-by-step guide to connecting ESCs to motors

Start by connecting the three motor wires to the respective ESC outputs. The order isn’t critically important but affects motor direction—use trial and error to confirm correct rotation. Secure connections with solder, ensuring no exposed metal.

Soldering tips and techniques for clean connections

Use a well-heated, clean tip soldering iron for neat solder joints. Apply solder to the joint, not the iron tip, for consistent flow. A rosin-core solder helps with adhesion and flow. Always check joints for cold solder signs—dull and cracked surfaces—and rework if necessary.

Verifying connections and troubleshooting issues

Once soldered, use a multimeter to check continuity and verify connections. If a motor doesn’t spin correctly, recheck the soldering joints and wire orientation. Swap any two motor wires if reverse motor direction is needed.

Mounting and Securing ESCs

Proper mounting ensures ESCs are secure and safe from environmental factors.

Options for physically securing ESCs to the frame

Use zip ties or heat shrink to hold ESCs in place. Double-sided foam tape offers vibration absorption. Position ESCs such that wires are unrestricted yet secure.

Using heat shrink and zip ties effectively

After securing wires with solder, cover them with heat shrink tubing to insulate and protect them from short circuits. Firmly zip tie bundled wires to avoid unwanted movement but not so tight as to damage them.

Ensuring protection against vibrations and impacts

Consider using vibration dampening materials between ESCs and the mounting point. This minimizes wear on solder joints and keeps electronics safe during hard landings.

Configuring ESC Settings

A correctly configured ESC is critical for optimal drone performance.

Introduction to ESC software and firmware

Modern ESCs can be configured via software like BlHeli Configurator. This interface allows for firmware updates, parameter setting, and calibration—all crucial for tailoring ESC behaviors to flight needs.

How to calibrate ESCs for optimal performance

Calibration aligns ESCs with your throttle inputs. Disable features like propellers, connect your battery, and follow BlHeli instructions to find the minimum and maximum throttle positions, ensuring smooth and predictable motor operation.

Using BlHeli or similar software for configuration

With BlHeli, you can set parameters such as motor direction, speed, and braking. Many pilots use it to fine-tune their drone’s response characteristics, balancing between speed and stability as desired.

Conclusion

Recap of key steps in motor and ESC installation

In summary, throughout the installation process, aligning your frame accurately, selecting compatible motors and ESCs, and ensuring firm and safe fixtures of every component are critical. Proper wire management can’t be overstated—it’s essential for avoiding future technical problems.

Tips for maintaining optimal performance

Regularly inspect all connections, especially solder joints, for wear or damage. Keep firmware updated and periodically check ESC settings to ensure everything aligns with your flight needs. After physical impacts or crashes, always recheck alignment and balance.

Next steps in building a racing drone

Having installed your motors and ESCs, you’re ready to proceed to frame assembly, camera installation, and finally to fine-tuning flight controls. Each step brings your racing drone closer to life, promising thrilling flights controlled by your adept craftsmanship and knowledge. Enjoy the journey!