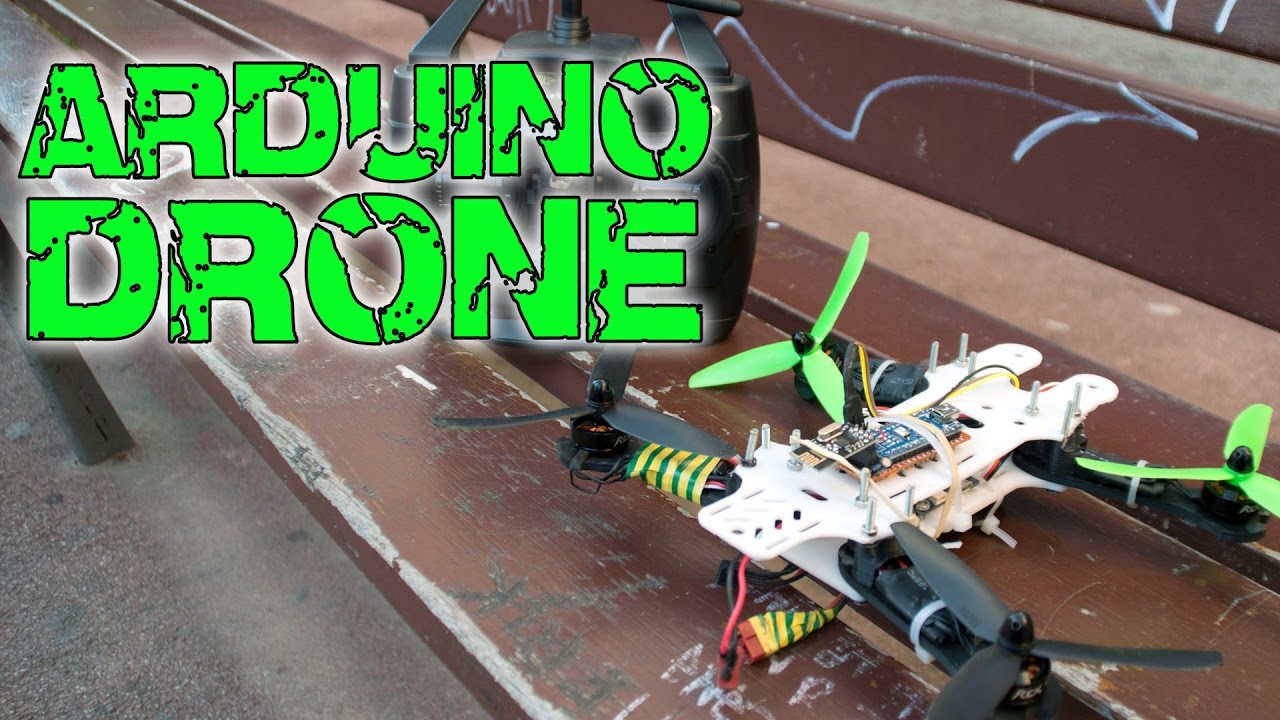

Creating your own drone can be a thrilling adventure, especially when you’re diving into the world of Arduino. In “Arduino Drone Part 1: Building the Flight Controller with Electronoobs,” you’ll embark on the first step by assembling a flight controller. Using an Arduino Nano paired with the MPU6050 gyro and accelerometer module, you’ll be setting the foundation for your drone’s brain. This guide will walk you through the setup, ensuring that you can stabilize and maneuver your drone with precision using the MultiWii platform.

As you solder data and clock pins and configure electronic speed controllers, you’ll learn valuable skills that can be applied to your future robotic projects. This comprehensive approach will help you understand how data from sensors is processed to control motor output, enabling stable flight. The journey doesn’t end here—upcoming sections will guide you through building the radio transmitter and receiver, leading to the final assembly of the drone. Get ready to soar to new heights with your very own custom-built drone!

A complete Arduino-based drone guide. The tutorial is split into sections. In the video, you create the flight controller using the Arduino NANO and MPU6050 gyro/accelerometer. To program the controller, you use the multiwii platform. Stay tuned for upcoming parts on the radio receiver/transmitter and the drone’s full construction.

Support my projects on Patreon: /electronoobs

My Q&A page: http://electronoobs.com/eng_preguntas…

PRINTERS

Ender 3 (167€): https://www.gearbest.com/3d-printers-…

SparkMaker SLA: https://www.gearbest.com/3d-printers-…

Crealitu CR10: https://www.gearbest.com/3d-printers-…

Coupon code: “11CR10EU” or “11CR10US”

ANET E10 (219$): https://www.gearbest.com/3d-printers-…

Coupon code: “Anete10us”

TEVO Tarantula (175$): https://www.gearbest.com/3d-printers-…

Coupon code: “Tarantulaus”

Creality CR10 MINI: https://www.gearbest.com/3d-printers-…

COUPON: CR10MINI

Anet A8: https://www.gearbest.com/3d-printers-…

Coupon code: “A8KIDA”

—————–LINKS——————-

Flight controller page: http://www.electronoobs.com/eng_robot…

Transmitter/receiver page: http://www.electronoobs.com/eng_robot…

Drone construction page: http://www.electronoobs.com/eng_robot…

Full tutorial page: http://www.electronoobs.com/eng_robot…

Multiwii download: http://www.electronoobs.com/eng_robot…

Complete part list: http://www.electronoobs.com/eng_robot…

PID tutorial: http://www.electronoobs.com/eng_robot…

—————MATERIAL—————

Arduino NANO: http://www.ebay.com/itm/Nano-V3-0-Min…

MPU6050: http://www.ebay.com/itm/MPU-6050-6DOF…

Drilled PCB: http://www.ebay.com/itm/15Pcs-Baklite…

Male pins: http://www.ebay.com/itm/5-PCS-40-Pin-…

12A ESC: http://www.ebay.com/itm/1-x-Emax-12A-…

—————SCHEMATICS———–

Flight controller schematic: http://www.electronoobs.com/eng_robot…

——————–CODE——————

MPU6050 test: http://www.electronoobs.com/eng_robot…

Multiwii download: http://www.electronoobs.com/eng_robot…

Like, share, and subscribe to keep me motivated. Thank you!

Materials and Components

Overview of Required Components

To construct an Arduino-based drone, you will need several essential components. The core of your setup will be an Arduino Nano, which acts as the main flight controller. You’ll also require an MPU6050 gyro/accelerometer to measure movement and orientation. Electronic Speed Controllers (ESCs) will be necessary to regulate the speed of the brushless motors, which are responsible for the drone’s thrust. In addition, you will need a power supply, connectors, and a few additional electronic components to solder everything together. Each component plays a vital role in ensuring that your drone flies accurately and efficiently.

Detailing the Arduino Nano

The Arduino Nano is a compact and versatile microcontroller board based on the ATmega328P. It’s the brain of your flight controller system, handling all processing tasks such as reading sensor data, calculating needed adjustments, and sending commands to the motors. Its small size allows for easy integration into drone designs where space and weight are critical factors. With multiple input/output pins, it provides sufficient connectivity to link with other components like the MPU6050 and ESCs, making it an excellent choice for DIY drone projects.

Understanding the MPU6050 Gyro/Accelerometer

The MPU6050 combines a three-axis gyroscope and a three-axis accelerometer, providing comprehensive orientation and motion data. This sensor helps the flight controller determine the drone’s attitude and movement, allowing for stable flight and angle control. Connecting to the Arduino via the I2C interface, it delivers real-time data that the controller uses to correct deviations and maintain level flight. Understanding the data from the MPU6050 is critical for programming the flight controller to respond appropriately to changes in position or orientation.

Explaining the Electronic Speed Controllers (ESCs)

Electronic Speed Controllers act as the link between the flight controller and the drone’s motors. They receive signals from the Arduino, adjusting the motor speed to control lift and direction. Each motor requires its own ESC, and for a typical quadcopter, you’ll use four in total. These ESCs are responsible for translating the PWM (Pulse Width Modulation) signals into power changes, thus enabling smooth and accurate throttle control. A stable power supply is essential, as it connects the ESCs to both the Arduino and the power source to ensure consistent signal delivery and power distribution.

Planning the Flight Controller

Understanding the Role of a Flight Controller

The flight controller is the central system that processes input from sensors, pilots, and peripherals, implementing commands that keep your drone airborne and stable. It collects data from the MPU6050 to determine the drone’s position and responds by adjusting motor speeds through the ESCs. The flight controller ensures the drone remains stable and can execute maneuvers by constantly recalculating and adjusting based on sensor input, essentially serving as the brain of your drone.

Designing the Initial Schematic

Creating a functional schematic is crucial for the layout and successful assembly of your flight controller. Begin by positioning the Arduino Nano and determine its connections to the MPU6050, ESCs, and the power supply. Your schematic must also include connections for input signals, such as the receiver’s PPM signal. When designing, take into account the pin layout on the Arduino Nano, ensuring all connections are accurate and that the flow of data and power is uninterrupted.

Placement and Layout Considerations

When planning your flight controller’s layout, consider where each component will sit to maximize stability and functionality. The MPU6050 should ideally be placed near the center for accurate orientation readings. The Arduino Nano needs to be accessible for programming and troubleshooting, while ESCs should be positioned to minimize wire length and reduce clutter. Your layout must also preserve balance and minimize interference among components to promote smooth operation and effective flight control.

Assembling the Hardware

Positioning the Arduino Nano

Once you have your schematic, carefully position the Arduino Nano on your PCB (Printed Circuit Board) or prototype board. Ensure that its placement allows for easy access to its connections and remains secure to prevent dislodging due to drone vibrations. By securing it properly, you reduce the risk of connection issues that could affect the flight controller’s performance.

Mounting the MPU6050

Mount the MPU6050 as centrally as possible on your board. This positioning helps ensure the most reliable data readings by keeping measurements accurate and directly reflective of the drone’s actual movements. Secure the sensor well to decrease the risk of vibrations affecting the readings, which could otherwise result in unstable flight.

Integrating the Electronic Speed Controllers

Connect each ESC to its respective motor and corresponding pin on the Arduino Nano. This integration ensures that every motor receives the correct signal independently, allowing for precise control over flight maneuvers. Ensure the connections are firm and that the wiring does not obstruct other components or affect the drone’s balance.

Creating the Printed Circuit Board (PCB)

Designing a PCB for your flight controller allows for a more compact and professional setup. Plan your board layout to accommodate all components while maintaining efficient electrical pathways for data and power. A well-designed PCB can significantly reduce the chance of loose connections and interference, leading to a more reliable and robust flight controller.

Wiring and Connections

Connecting the MPU6050 to the Arduino

Wire the MPU6050 to the Arduino Nano using the I2C protocol, connecting the data line to A4 and the clock line to A5. Properly secure the ground and voltage lines to ensure stable and uninterrupted power and data transfer between the sensor and the flight controller. Double-check each connection to prevent shorts or faulty readings.

Establishing Motor Outputs

Each ESC needs a connection to the Arduino Nano’s PWM pins—these typically include digital pins 3, 9, 10, and 11 for a quadcopter. Ensure each pin outputs the correct signal, allowing the ESCs to modulate motor speeds based on input from the flight controller. Accurate connections in this step are crucial for balanced thrust and stable flight.

Setting Up the PPM Signal Input

The PPM signal from your radio receiver must be connected to the correct pin on the Arduino Nano, often digital pin 2, to receive flight commands. Proper setting ensures that the flight controller can interpret multiple channel signals through a single line, simplifying the wiring while enabling comprehensive control input from the pilot.

Ensuring Proper Power Supply

Your flight controller requires a stable 5V power supply. This is usually provided by one of the ESC’s BEC (Battery Elimination Circuit) outputs. Ensure that the power supply connections are secure, and verify that the voltage levels are consistent, as unstable power can lead to erratic controller behavior or loss of control.

Introduction to Multiwii Platform

What is Multiwii?

Multiwii is an open-source flight control platform originally designed for RC drones. It provides comprehensive software that manages sensor data interpretation, signal processing, and motor control to facilitate various airborne platforms, including multicopters, planes, and helicopters. Multiwii is known for its versatility and adaptability to different drone configurations and controller setups.

Advantages of Using Multiwii

Using Multiwii offers several advantages: it’s flexible, regularly updated, and supports a vast array of features allowing customization for different drone types. With a strong user community, it provides extensive documentation and support, making it an ideal choice for enthusiasts and professionals alike. Multiwii simplifies the programming process by offering a tested vehicle for your flight control system.

Downloading and Installing Multiwii

To set up Multiwii, download the latest version from the official Multiwii repository. After extracting the files, locate the Arduino code and the Java-based GUI within the folders. Follow installation instructions to integrate Multiwii into your Arduino IDE, which will allow you to upload the necessary code onto your Arduino Nano to transform it into a capable flight controller. This process also includes setting up a real-time tuning and configuration GUI, enhancing your ability to manage and adjust the flight controller settings dynamically.

Programming the Flight Controller

Configuring the Multiwii Arduino Code

Once installed, open the Multiwii sketch in the Arduino IDE. Begin configuring the settings based on your drone’s specifications by modifying the configuration file. Here, you will define core aspects like sensor types, motor layout, and other parameters crucial for your quadcopter’s operation.

Setting Up Multicopter Type

Identify your multicopter’s type—in this guide, a Quad X configuration is used. Adjust the Multiwii code by commenting in the Quad X setup while commenting out any irrelevant configurations. These changes ensure that the flight controller applies the appropriate control algorithms for your specific drone design.

Defining Throttle Parameters

Set the throttle parameters to define upper and lower limits. Modify the minimum throttle value to ensure the motors keep spinning at low RPM when the drone is idling or during minor adjustments. Establishing maximum throttle ensures that the motors do not exceed their capacity. Proper throttle parameters are key to maximizing efficiency and responsiveness.

Configuring PPM Communication

Set up PPM communication by configuring the Multiwii code to handle the PPM signal input from your receiver. This involves specifying the order of channels and ensuring the code can interpret each adequately, translating stick movements into actual commands for the drone. Clear communication channels are critical to pilot input responsiveness.

Testing the Setup

Compiling and Uploading the Code

With your configuration complete, compile the Multiwii code in the Arduino IDE, checking for any errors. Once verified, connect the Arduino Nano to your computer and upload the code. This step transforms your hardware assembly into a functional flight controller, paving the way for further testing.

Utilizing the Java Application

Open the Multiwii GUI Java application to monitor real-time data from your flight controller. By connecting it to your Arduino, you can visualize sensor data, verify readings, and adjust parameters dynamically. This visual feedback helps troubleshoot issues and optimizes flight performance by providing an interactive tuning environment.

Calibrating the Accelerometer

Calibration is essential for the accurate functioning of the MPU6050. Use the Multiwii GUI to lay the controller flat and execute accelerometer calibration procedures. Proper calibration ensures that the sensor provides precise readings, crucial for stable flight and accurate maneuver responses.

Troubleshooting Common Issues

Common issues such as connection problems, inaccurate sensor data, or incorrect motor responses can arise. Use systematic troubleshooting by verifying connections, reviewing code settings, and utilizing the Multiwii GUI for live feedback. Identifying and correcting these issues at this stage helps prevent flight mishaps.

Fine-Tuning the Flight Controller

Understanding the PID Control

PID (Proportional, Integral, Derivative) control is a method used to maintain desired positions and attitudes in flight by constantly adjusting control signals. Grasp the significance of PID settings in your drone’s control response. Fine-tuning these parameters is necessary for achieving desired stability, response sharpness, and consistent flight characteristics.

Calibrating Sensors

Maintain sensor accuracy by periodically recalibrating your MPU6050. Ensure that recalibration is conducted under stable conditions to maintain high data integrity. Doing so inevitably improves reliability and flight quality over time.

Adjusting Flight Commands

Adjust flight commands through the Multiwii platform by altering responsiveness to control inputs. This involves refining PID values, throttle responses, and input dead zones to achieve a flight experience tailored to your preferences. Such adjustments enhance maneuverability and pilot confidence.

Preparing for the Next Steps

Discussing Upcoming Parts of the Build

With the flight controller operational, the next steps involve assembling remaining components of your drone. This includes integrating all physical components into a single drone chassis. Future work will cover integrating a radio control system and tuning the complete assembly for cohesive operation.

Introduction to Building the Radio Transmitter and Receiver

Upcoming tutorials will guide you through building a custom radio transmitter and receiver using Arduino platforms. This process expands your DIY project, enabling you to create a complete communication system for remotely controlling your drone.

Overview of Final Drone Assembly

The final phase involves the assembly of your complete drone, encompassing both the electronics and physical materials like frames, propellers, and battery systems. This integration involves meticulous testing, ensuring each part works harmoniously to achieve effective flight.

Conclusion

Recap of Accomplishments

At this stage, you have laid the groundwork by successfully creating a functional flight controller using the Arduino Nano, MPU6050, and Multiwii platform. This involved careful planning, wiring, programming, and calibration of your drone’s control system.

Importance of Each Component

Each part of your flight controller—from the Arduino Nano to the ESCs—is crucial to its function. Understanding the role of each component provides better insight into drone operation, empowering you to troubleshoot and enhance the system.

Encouragement to Continue the Project

Congratulations on reaching this milestone! Your journey in building a fully functional Arduino-based drone progresses from here. Stay motivated, explore methodologies for improving flight capabilities, and immerse yourself in the rewarding process of innovation and learning through further building and fine-tuning of your drone system. Happy flying!