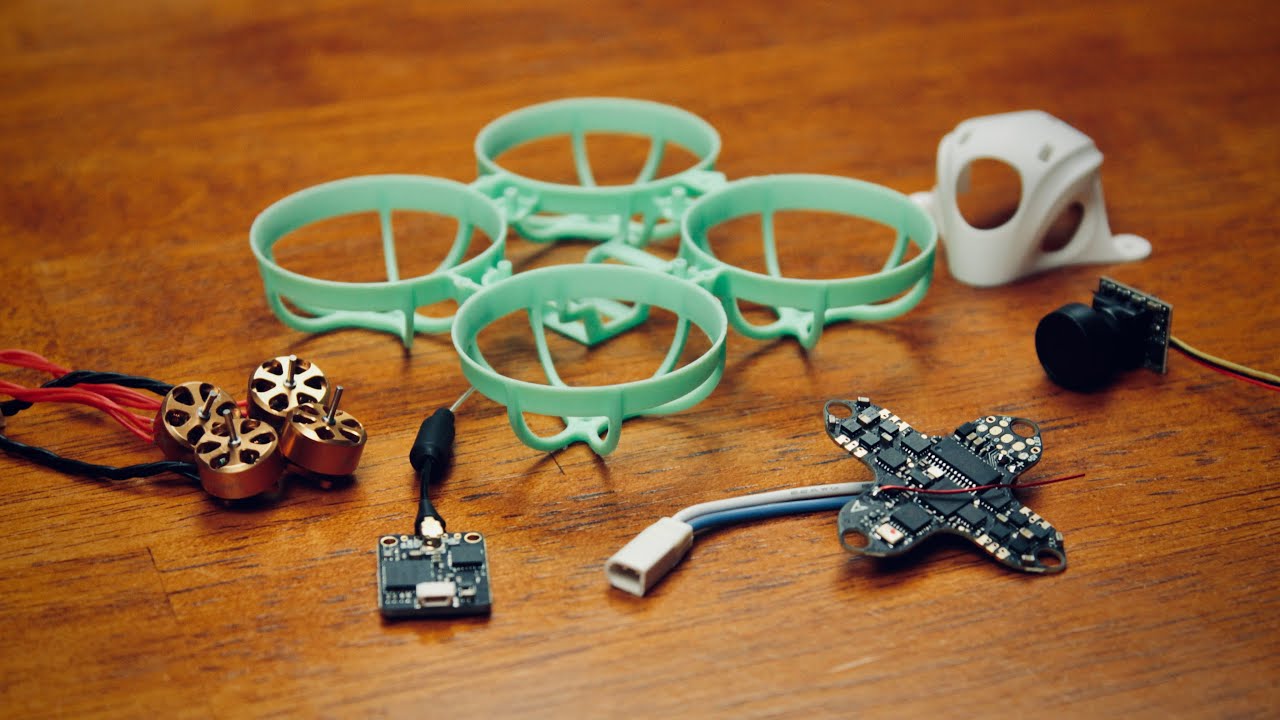

You’re in for an exciting journey as you explore the world of building your very own micro racing FPV drone without breaking the bank. This project, led by the talented Wynn FPV, walks you through assembling a Tiny Whoop using a clever mix of Newbie Drone and Beta FPV parts. With clear steps and helpful insights, you’ll gain the confidence to create a sleek drone that balances cost and performance perfectly.

From selecting the right flight controller to mastering the art of soldering, you’ll learn each component’s role in crafting a high-quality drone for just $120. This guide ensures you’re equipped with the knowledge and skills needed for a streamlined build process, even if you’re new to the world of drones. So, gather your parts and tools, and embark on constructing an innovative drone, ready to soar through the skies and capture incredible views.

Sorry for the poor audio; your dining room has quite an echo… If you’re interested in building this yourself, I’ll provide the parts list here.

Flight Controller – Buy here

VTX – Buy here

Camera – Buy here

Frame – Buy here

Motors – Buy here

SHOUT OUT to your Sponsors:

Choosing the Right Parts for Your Micro Racing FPV Drone

Overview of Available Brands

When building your micro racing FPV drone, choosing reputable brands is crucial to ensure that the components are reliable and compatible. Popular brands like BetaFPV and Newbie Drone are well-regarded in the drone community for their quality and innovation in micro drone parts. BetaFPV is known for its cutting-edge flight controllers and robust frames, while Newbie Drone is favored for its powerful motors and durable components. By opting for these brands, you tap into a wealth of community support and proven products that can significantly improve your drone-building experience.

Criteria for Selecting Drone Components

When picking the parts for your drone build, several criteria need to be considered. Firstly, compatibility is paramount; all components must work harmoniously. Next, consider the weight of each part, as a lighter drone is generally more nimble. Additionally, the quality and reliability of the parts are crucial—choosing components from trusted brands can reduce the likelihood of mid-air failures. Don’t forget to take into account the performance specifications, such as motor KV ratings and battery voltage compatibility, which influence the drone’s speed and flight time.

Budget Considerations

Creating a micro racing FPV drone can be affordable if you plan wisely. You’ll want to balance cost with quality to ensure you’re not sacrificing performance. The total component cost for this specific build is calculated at approximately $117.95. This budget-friendly option uses a mixture of BetaFPV and Newbie Drone parts, providing a reliable and high-performing drone without breaking the bank. Ensure to allocate some budget for tools and necessary safety equipment, which are essential for the assembly process.

Essential Components and Their Costs

Flight Controller: Beta FPV 1S 5A F4

The flight controller is the heart of your drone. The BetaFPV 1S 5A F4 flight controller offers excellent performance, providing stability and control even at high speeds. Priced at $39.99, this model is renowned for its cutting-edge technology and reliability, making it an excellent choice for a micro racing drone.

VTX: Beta FPV M03 Overview

For video transmission, the BetaFPV M03 VTX is an optimal choice, priced at $19.99. With up to 400 mW of power, it offers strong and clear signal capability, crucial for maintaining visual contact with your drone during fast-paced racing. Its small form factor fits perfectly in a micro build.

Camera: Beta FPV C03 Features

The BetaFPV C03 camera is compact but impressive. At just $19.99, it provides sharp image quality with wide-angle coverage, ensuring you don’t miss any part of your racing path. This camera is accompanied by a lightweight canopy, simplifying installation and adding protection.

Frame: Meteor 65 Characteristics

The Meteor 65 frame from BetaFPV, priced at $4.99, is an excellent option for its durability and lightweight structure. Despite its delicate appearance, it is designed to withstand crashes, a common occurrence in drone racing.

Motors: Newbie Drone 0802 Specifications

Motors are pivotal for speed and handling. The Newbie Drone 0802 motors come in at $32.99 for a set of four, featuring an 18,000 KV rating that ensures rapid acceleration and agility, making them perfect for high-speed maneuvers needed in racing.

Summary of Total Cost

The parts listed bring the total expenditure for a top-notch micro racing FPV drone to around $117.95. This budget-friendly build ensures you get high performance without overspending, making it an attractive option for hobbyists and seasoned racers alike.

Tools and Equipment Needed for Assembly

Soldering Iron and Accessories

A quality soldering iron is crucial for connecting your drone’s electronic components. You’ll need various soldering tools, such as solder wire and a solder sucker, to manage mistakes. A temperature-controlled soldering iron is recommended for precision and reliability.

Screwdriver Set

A diverse screwdriver set is needed to assemble the drone, as different parts will require different sizes. Ensure you have both Phillips and flathead options, as the screws you’ll encounter may differ.

Wire Cutters and Strippers

Wire cutters and strippers are essential for cutting and preparing the wires for soldering. They ensure clean cuts and appropriate lengths, which is crucial for neat and effective connections between components.

Safety Equipment

Safety goggles and possibly a pair of gloves are recommended to protect yourself during assembly. The goggles will shield your eyes from solder splashes and any debris when working with the frame and motors.

Preparing for the Build

Setting Up Your Workstation

Arrange your workspace to be clean and organized, free from clutter. Good lighting is essential to handle small parts effectively, and a proper workbench can provide a stable area to work on your build.

Organizing the Parts and Tools

Before starting, lay out all your tools and components to ensure everything you need is within reach. This preparation saves time and helps avoid misplacing small parts during the assembly process.

Reading the Build Diagrams

Familiarize yourself with any build diagrams or instructions specific to your parts. Understanding the layout and connection points will make the assembly more straightforward and help you avoid mistakes.

Building the Flight Controller Setup

Installing Grommets on the Flight Controller

The first step in the assembly is installing the grommets on your flight controller. They function as spacers, providing a cushioning effect that reduces vibrations affecting the flight controller, ensuring smoother operation.

Tinning Motor Pads

Tinning involves applying a thin layer of solder to the motor pads on your flight controller. This process is critical for making strong, reliable solder joints, essential for effective electrical connections.

Tinning VTX Connection Pads

Similarly, tin the VTX connection pads on the flight controller. This step ensures that connecting your VTX is straightforward, minimizing any risk of a bad connection.

Attaching Motors to the Flight Controller

Cutting Motor Wires to Proper Length

Cut the motor wires to an appropriate length to ensure they fit neatly onto the flight controller without excess slack. This precision reduces the weight slightly and keeps the build clean.

Tinning Motor Wires

Before soldering the motor wires to the flight controller, tin them. This preparation allows for a stronger bond when you solder, enhancing the durability of your connections.

Soldering Motors to the Flight Controller

Solder each motor onto the flight controller. The specific order of the wires is adjustable in the software, so don’t worry too much about getting them in a specific order initially.

Connecting the VTX and Camera System

Tinning and Soldering VTX Wires

Prepare the VTX wires by tinning them first, then solder them to the corresponding VTX pads on the flight controller. This connection will transmit your video feed to your goggles.

Mounting the Camera in the Canopy

Attach the camera securely into the provided canopy. The mounting should be snug to prevent the camera from moving during flight, which could disrupt the video feed.

Connecting the Camera to VTX

Once mounted, connect the camera to the VTX. This step completes your video transmission system, crucial for piloting the drone using FPV goggles.

Final Assembly

Mounting Components onto the Frame

Start with positioning all your components onto the frame. The flight controller, motors, and VTX need to be secured in place, ensuring they do not move during vigorous flight.

Securing Flight Controller and Canopy

Securely fasten the flight controller and the canopy onto the frame using the provided screws. Proper securing is essential to avoid any disturbance in flight stability.

Attaching Motors to the Frame

Mount each motor onto the frame’s arms. Make sure they fit firmly and are properly oriented, as properly aligned motors are essential for balanced flight.

Testing and Troubleshooting

Initial Test Procedures

Before your first flight, conduct initial tests to ensure everything is functioning correctly. These tests include checking motor spins, ensuring the VTX transmits video, and confirming the flight controller runs smoothly.

Common Issues and Solutions

Some common issues may include motors not spinning correctly, VTX signal problems, or a lack of response from the flight controller. In most cases, rechecking solder connections, ensuring firmware compatibility, and confirming power supply are effective solutions.

Configuring with Software Tools

Use software tools like Betaflight Configurator to fine-tune your drone. This configuration process is vital to setting the correct parameters for flight controls, ensuring that your drone responds quickly and accurately to commands.

Conclusion

Summary of the Build Process

The process of building an FPV micro racing drone involves careful selection of components, meticulous assembly, and thorough testing. Beginning with your choice of brands and components, through the assembly process to the final testing phase, each step is crucial for achieving a durable and high-performing racing drone.

Who Should Attempt This Build?

This build is most suitable for those who have some experience with electronics and soldering, as the components require precision in assembly. Beginners interested in drones can certainly learn through this process but should approach it patiently and be prepared to practice soldering safely.

Final Thoughts and Recommendations

Building your own micro racing FPV drone can be a rewarding endeavor, providing insight into the workings of drones while allowing for customization to suit personal preferences. By carefully following the steps and considerations laid out, you can achieve a cost-effective yet high-performing drone, offering both the thrill of racing and the satisfaction of a successful DIY project.