In “DIY Drone Mods – Calculate How Much Weight A Drone Can Lift,” you’ll uncover an easy way to figure out your drone’s maximum lift capacity using just an electronic scale. No need to risk your drone; you can verify its limits safely and accurately. By positioning your drone over a scale and observing the change in weight when it attempts to lift, you’ll know exactly how much your drone can handle without pushing it to its limits.

This method ensures you get the most out of your drone while keeping its motors in safe and working condition. Just like you wouldn’t want to overstrain a car engine by constantly redlining it, the same care applies to your drone’s motors. Knowing how to calculate your drone’s payload can help prolong its life and save you from unnecessary and costly repairs. Stay informed and enjoy your drone without worry, all while making sure it stays in tip-top shape.

Understanding Drone Payload Capacity

Definition of Payload

When it comes to drones, the term “payload” refers to everything that a drone is carrying besides its own essential components. This might include cameras, sensors, delivery items, or any additional equipment required for specific tasks. Essentially, it’s the sum of all the additional weight that a drone is tasked with lifting and transporting during its flight, above and beyond the weight of the drone itself.

Factors Affecting Payload Capacity

Several factors can influence a drone’s payload capacity. The design and model of the drone are primary determiners, where high-performance drones often have larger capacities compared to hobbyist models. The power of the drone’s motors, the efficiency of its propellers, and the overall aerodynamics also play crucial roles. Environmental factors such as wind speed and altitude can further affect how much weight a drone can safely and effectively transport. It’s crucial to consider all these variables to understand and plan for your drone’s payload capability.

Importance of Knowing Payload Limitations

Being aware of your drone’s payload limitations is critical for safe operations and ensuring the longevity of your equipment. Overloading your drone can lead to reduced flight stability, increased motor strain, and eventual damage. By understanding the boundaries of what your drone can manage, you can better plan your missions, safeguard your equipment, and avoid costly repairs or replacements.

Basic Principles of Drone Lift

How Drones Achieve Lift

Drones achieve lift through a careful balance of physics and technology. Essentially, lift is created when the drone’s propellers spin, pushing air downwards. This action forces the drone upwards thanks to Newton’s third law: for every action, there is an equal and opposite reaction. This upward force must exceed the gravitational force pulling the drone downward to achieve and maintain flight.

Role of Drone Propellers

Propellers are vital in the lift equation, as they are responsible for generating the necessary force. The size, shape, and angle of the propellers (also known as the pitch) significantly influence the amount of lift produced. Propellers with a steeper pitch can move more air, thereby creating more lift, but may also require more powerful motors to do so efficiently.

Impact of Motor Strength on Lift

The strength and efficiency of a drone’s motors are directly tied to its ability to produce lift. Stronger motors can turn propellers faster and handle larger propellers that can push more air, thus increasing a drone’s potential to carry heavier payloads. However, more robust motors also consume more battery power, which can shorten flight times, a trade-off that needs careful consideration.

Tools for Measuring Drone Payload Capacity

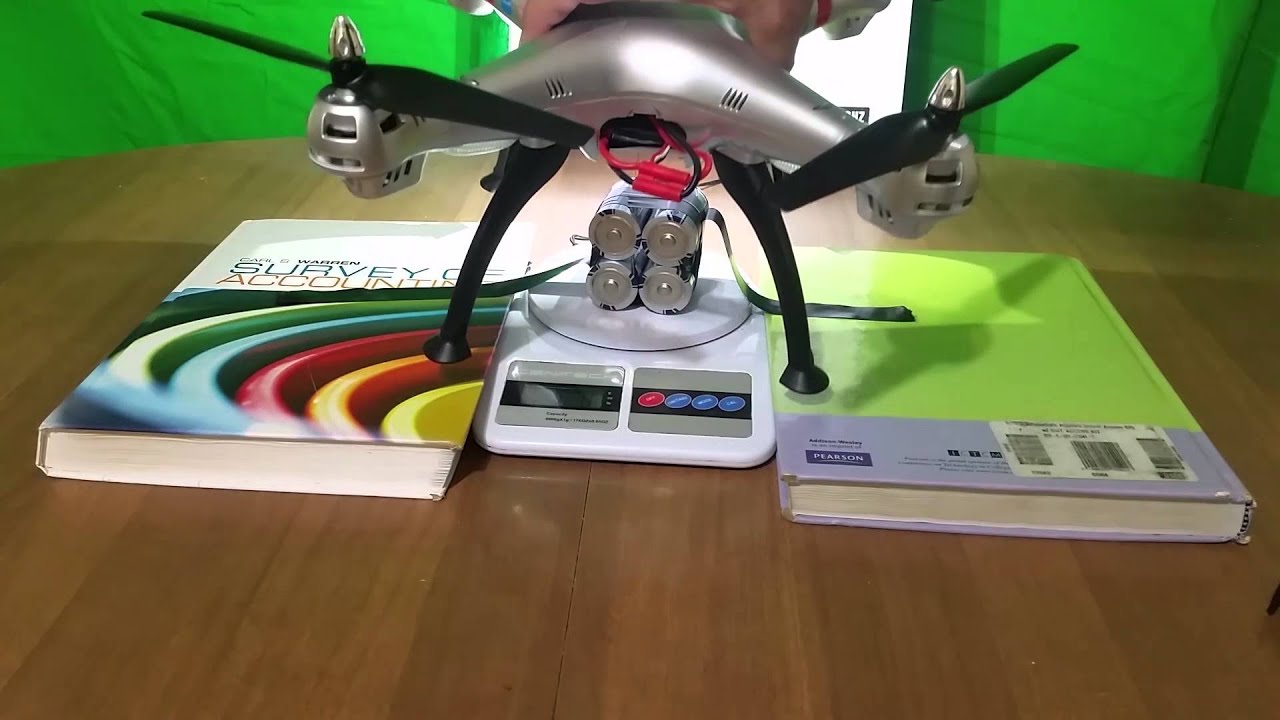

Electronic Scales: A Simple Tool

One simple yet effective tool for measuring a drone’s payload capacity is an electronic scale. By allowing you to determine the weight of additional loads, electronic scales can help calculate how much weight your drone can carry effectively. This simple method provides a practical, real-time assessment of payload capacity without risking your drone in the process.

Calibration Techniques

Calibration of measurement tools is crucial for accurate readings. For an electronic scale, this involves resetting the scale with no weight, then adding known weights to ensure it reads correctly. In the context of drones, you’ll need to ensure the scale is properly zeroed before attaching your drone and additional payload to obtain precise measurements.

Accuracy and Limitations of Measurement Tools

While electronic scales provide excellent convenience and accuracy, they are not without limitations. Factors such as surface stability and environmental conditions can affect readings. Additionally, scales have a maximum weight limit, which must not be exceeded for accuracy. Being aware of these constraints helps you get the most reliable data.

Step-by-Step Guide to Calculate Payload Capacity

Setting up the Electronic Scale

Begin by placing your electronic scale on a stable, flat surface. A secure foundation is crucial for precise measurements. Turn on the scale and reset it to zero before placing any items on it, ensuring accurate and consistent results.

Using Counterweights for Calibration

To calibrate, use known weights as counterweights on the scale. For instance, place several items, such as batteries or similar objects, and verify that the scale reflects their exact weight. If discrepancies occur, recalibrate until consistent accuracy is achieved.

Assessing Drone Lift with Real-time Measurement

With your scale ready, attach your drone using a tape or another safe method, ensuring no physical interaction from your side. By operating the drone, observe changes in the scale’s reading as the drone lifts off. The negative weight displayed signifies the drone’s lift capability, providing a real-time measurement of its payload capacity.

Modifications to Increase Drone Payload Capacity

Upgrading Drone Motors

One effective method to increase your drone’s payload capacity is by upgrading the motors to more powerful ones. This enhancement allows the drone to generate more lift and effectively carry heavier loads. However, such changes require careful evaluation of compatibility with other drone components, particularly regarding energy consumption and battery life.

Enhancing Propeller Efficiency

Improving propeller efficiency is another avenue to increase payload capacity. Larger or more aerodynamically efficient propellers can move more air, producing additional lift. This often pairs well with motor upgrades, offering a balanced approach to enhance overall performance without overwhelming your drone’s power system.

Reducing Drone Weight for Better Capacity

Reducing the drone’s own weight can significantly boost its payload capacity. By minimizing unnecessary equipment and opting for lighter materials, you manage to free up more lift capability for the payload. Each gram saved in drone weight translates into more capacity for additional equipment or deliveries.

Potential Risks of Exceeding Payload Capacity

Impact on Drone Lifespan

Overloading your drone can drastically shorten its lifespan. When a drone operates constantly near its maximum payload capacity, it subjects its components, especially the motors, to increased stress and wear. This situation can lead to more frequent breakdowns and a reduced operational lifespan.

Effect on Flight Stability

Exceeding payload limits can seriously impair a drone’s stability during flight. Heavier loads alter the drone’s center of gravity, making it harder to control and potentially leading to erratic movements or even crashes. A stable flight is crucial for executing precise maneuvers and safe operations.

Consequences of Motor Overheating

Pushing your drone beyond its intended load capacity often results in motor overheating. This condition arises when motors work harder to manage excessive weight, generating more heat than they can dissipate effectively. Over time, this can cause permanent damage to the motors, creating safety hazards and increasing maintenance costs.

Testing Your Drone for Maximum Payload

Initial Test Flights

Commence with light payloads to understand your drone’s limits progressively. These initial test flights are critical for collecting data on how various weights impact your drone’s performance. Start small and gradually increase the load, observing how the drone handles each increment.

Observing Drone Performance Under Load

Pay close attention to how your drone maneuvers under different loads. Look for signs of strain, such as sluggish responses or unusual vibrations. Document these behaviors to help gauge how much weight your drone comfortably carries without compromising its operational integrity.

Safety Precautions During Testing

Ensure your testing environment is safe and clear of obstacles. Use open, controlled spaces where you can carefully observe and manage your drone’s performance without endangering people, wildlife, or structures. Prioritizing safety minimizes the risks associated with testing payload extremes.

Maintenance Tips for Drones with High Payloads

Regular Motor Inspections

Frequent inspections of motor conditions are vital when regularly operating your drone near its payload capacity. Check for wear and tear, unusual noises, or any signs of overheating. Early detection of issues can prevent costly repairs and prolong your drone’s functional lifespan.

Propeller Maintenance

Propellers play a crucial role in lift and should be inspected and maintained regularly. Look for and address any damage or imbalance to ensure they remain in optimal condition. Proper care prevents inefficiencies and makes sure your drone lifts payloads safely and effectively.

Battery Care and Management

Drones carrying heavy payloads consume more energy. Thus, maintaining your battery for optimal performance is essential. Regularly check the battery health and charge cycles, and store them according to manufacturer guidelines. Well-maintained batteries ensure longer flights and prevent mid-air failures.

Cost Implications of DIY Drone Modifications

Budgeting for Upgrades

Planning your budget for drone modifications helps manage costs effectively. Upgrading motors and propellers or reducing drone weight requires investing in quality components. By establishing a clear budget, you can prioritize modifications based on immediate needs and future benefits.

Unexpected Expenses to Consider

Modifications can sometimes lead to unforeseen costs, such as additional parts for compatibility or unexpected repair needs. Account for these possibilities in your budget to avoid financial strain and ensure that modifications do not overextend your resources.

Long-term Financial Benefits of Modifications

Investing in DIY drone modifications may seem costly upfront but can offer substantial long-term financial benefits. Enhanced payload capacity can lead to more efficient operations and open up new applications for your drone, generating greater value and returns on your investments.

Conclusion

Summary of Key Points

In summary, understanding and managing a drone’s payload capacity is crucial for efficient and safe operations. From acknowledging the basic principles of lift and the tools for measurement to the potential risks and benefits of modifications, several factors contribute to optimizing your drone’s performance.

Final Thoughts on Payload Management

Effective payload management not only extends your drone’s lifespan but also maximizes its utility, allowing you to execute more complex tasks reliably. Always remain within the operational limits to avoid unnecessary wear and accidents.

Encouragement for Safe and Responsible Drone Operation

In the world of drones, safety and responsibility cannot be overstated. Whether you’re a hobbyist or a professional, consistently prioritize safe practices and informed decisions. With proper care and insights into payload management, the skies are truly the limit.