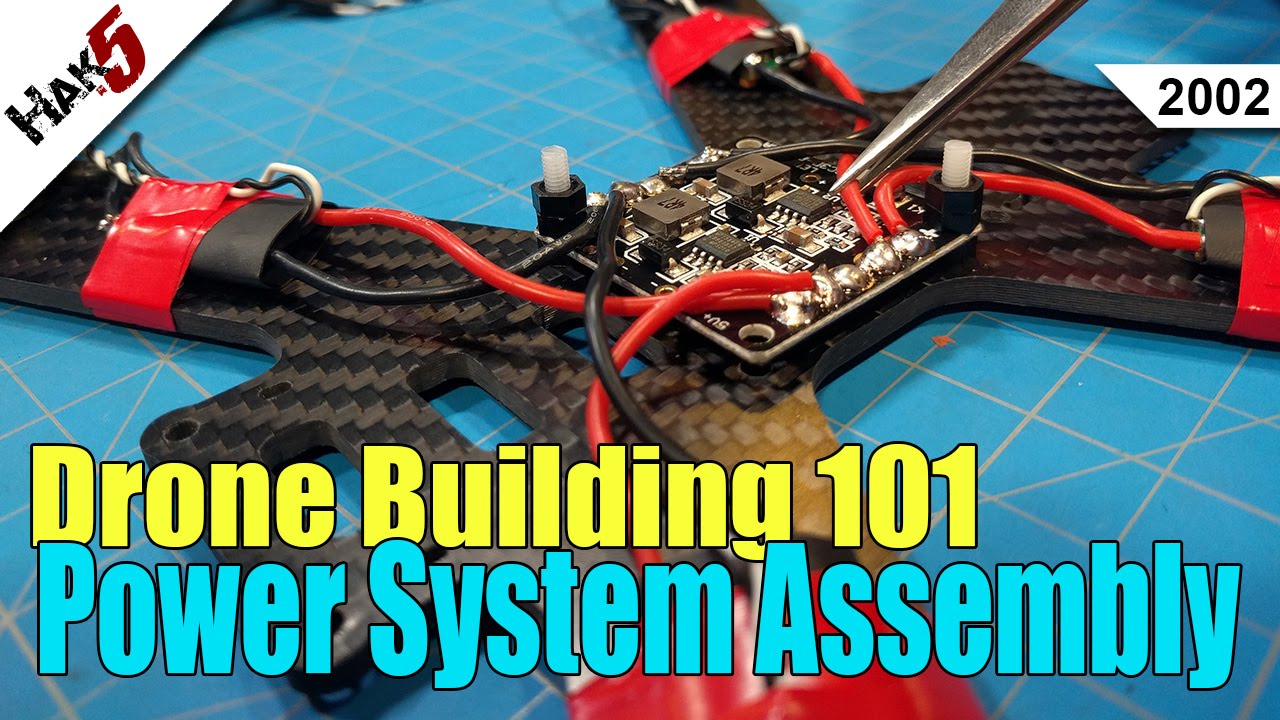

In the latest of Hak5’s “Drone Building 101” series, you’re in for an engaging guide on assembling the power system for a sub-250g quadcopter. Darren Kitchen and Shannon Morse take you step-by-step through the process of using lightweight components like carbon fiber frames and nylon screws to keep your drone nimble and avoid the hassle of FAA registration. You’ll start with essential elements like the power distribution board and NAZE32 flight controller, all while ensuring that your wiring and soldering are on point for maximum efficiency and safety.

As you follow along, you’ll uncover tips and tricks to avoid common pitfalls, such as balancing weight with component quality. With Hak5’s years of experience in the InfoSec industry and a supportive community at your back, you’re encouraged to embrace the thrill of drone building. Plus, they highlight where to find affordable parts, emphasizing the importance of being prepared with backups. Whether you’re a seasoned hobbyist or a curious newcomer, this episode promises a fun and informative experience, helping you lay the groundwork for even bigger drone projects in the future.

Hak5 — Cyber Security Education, Inspiration, News & Community since 2005:

In our second episode of season 20, you continue your drone build starting with the power system assembly.

Shop: http://www.hakshop.com

Support: /threatwire

Subscribe: /hak5

Our Site: http://www.hak5.org

Contact Us: /hak5

You can find cheaper parts from China direct resellers. It is always advised to buy extras of each component in case of DOA or issues during assembly. These Amazon links are for Shannon’s Amazon Associates account. By purchasing via these links, you help fund future podcasts – thank you!

-

Carbon Fiber 210 mm H frame (QAV210 or similar)

-

Power Distribution Board with 5 Volt and 12 Volt regulators

-

M2 Nylon Standoffs and Screws

-

NAZE32 Flight Controller

-

4x 20 Amp Electronic Speed Controllers with BLHeli firmware

-

4x Brushless Motors, either 1804 2300-2400KV or 1306 3100KV

-

4x Carbon Fiber 5030 Propeller either 3-hole or 1-hole depending on motor mount (2 clockwise, 2 counter-clockwise)

-

1x Spektrum compatible DSM2 or DSMX Satellite Receiver

–-~~~-–

Please watch: “Bash Bunny Primer – Hak5 2225”

• Bash Bunny Primer – Hak5 2225

–-~~~-–

Founded in 2005, Hak5’s mission is to advance the InfoSec industry. They do this through award-winning educational podcasts, leading pentest gear, and inclusive community – where all hackers belong.

Understanding the Basics: Introduction to Drone Building 101

Overview of Hak5’s educational series

Welcome to the exciting world of drone building! As you embark on this journey, you’ll find that it’s not just about assembling pieces, but about understanding the intricacies of electronics and aerodynamics. Hak5, known for its contributions to the InfoSec community since 2005, has put together a fantastic educational series called “Drone Building 101.” In this series, Darren Kitchen and Shannon Morse guide you through the steps of building a drone from scratch. Season 20’s second episode dives into the core of drone construction: the power system assembly. This episode is pivotal for beginners, offering insights and practical knowledge crucial for any aspiring drone builder.

Focus on power system assembly

In this episode, you’ll focus on the power system assembly—a fundamental step in the drone building process. A well-assembled power system ensures your drone has the required energy efficiency and performance. Darren and Shannon delve into setting up the power distribution board, connecting electronic speed controllers, and integrating the battery—all critical components for getting a drone in the air. Proper understanding and execution of this stage are essential as they influence the drone’s overall functionality and safety.

Importance of learning drone building

Building a drone isn’t just a hobby; it’s a gateway to understanding technology and engineering principles. Learning to construct a drone empowers you to customize, repair, and innovate your own unmanned aerial vehicles. It also strengthens your problem-solving skills and provides a deep sense of accomplishment. With the rising popularity of drones in various fields such as photography, delivery services, and even agriculture, knowledge in this area can be a valuable asset.

Planning Your Build: Choosing the Right Components

Recommended frame: Carbon Fiber 210 mm H frame

The foundation of your drone is its frame, and choosing the right one is crucial. For this build, a Carbon Fiber 210 mm H frame is recommended. This frame, known for its durability and lightweight properties, is suitable for a variety of drone types, making it a versatile choice for beginners. The H frame design provides an excellent balance between stability and maneuverability, ensuring a smooth flight experience. Additionally, its spacious layout offers enough room to house all essential components while maintaining the drone’s structural integrity.

Selecting the power distribution board with 5V and 12V regulators

When planning your build, selecting a power distribution board with 5V and 12V regulators is pivotal. This component distributes the battery’s power to all necessary systems, such as the flight controller and electronic speed controllers. The dual voltage regulators offer flexibility, allowing various components to operate at their required voltages, enhancing the drone’s efficiency. A reliable power distribution board ensures stable power flow and is vital for maintaining a balanced and responsive drone.

Opting for M2 Nylon Standoffs and Screws for lightweight builds

For a sub-250g build, managing weight is key to avoiding FAA registration requirements. Opting for M2 Nylon Standoffs and Screws contributes significantly to reducing the overall weight of your drone. Nylon components are not only lighter than traditional metal ones but also offer sufficient strength for securing parts in place. Their use helps maintain structural integrity while keeping your drone’s weight within the desired limits.

Central Control: Setting Up the Flight Controller

Introduction to NAZE32 Flight Controller

One of the most critical components of your drone is the flight controller, which acts as the brain of the operation. The NAZE32 Flight Controller is an excellent choice for beginners. It is renowned for its ease of use and reliable performance, making it ideal for first-time builders. This controller handles stabilization, communication with the drone’s sensors, and integration with your remote control systems.

Installation process and setup tips

Installing the NAZE32 requires careful attention to wiring and component orientation. Begin by mounting the flight controller securely on your drone’s frame, using vibration-dampening mounts if possible. Ensure that the wiring does not obstruct any moving parts and that all connections are solid. Follow the setup process by configuring the controller using software recommended by Hak5, ensuring that all parameters are accurately set for optimal flight performance.

Importance of accurate calibration

Accurate calibration of the NAZE32 is paramount for a successful flight. Calibration ensures that the flight controller accurately reads sensor data, adjusts motor speeds, and responds to your commands. Calibration should be performed on a flat surface, following guidelines provided in tutorials from the Hak5 series. Investing time in this step will lead to a more stable and responsive drone, enhancing your flying experience.

Electronic Speed Controllers: Assembly and Configuration

Choosing 20 Amp Electronic Speed Controllers with BLHeli firmware

Selecting the right Electronic Speed Controllers (ESCs) is crucial for your drone’s performance. For this build, 20 Amp ESCs running BLHeli firmware are recommended. These ESCs are known for their reliability and compatibility with modern drone motors. The BLHeli firmware offers advanced motor control, which helps improve your drone’s efficiency and responsiveness during flight.

Wiring and soldering guidelines

Proper wiring and soldering are essential for a successful ESC installation. Ensure that wires are cut to the appropriate length to avoid excess weight and potential signal interference. When soldering, apply heat only for the necessary time to prevent damage to the components. It’s crucial to double-check all connections for secure solder joints, as loose connections can lead to unpredictable behavior or damage.

Ensuring efficiency and safety in ESC setup

A well-configured ESC setup not only optimizes performance but also enhances safety. Ensure that the motors spin in the correct direction as specified for your drone’s configuration. Incorrect motor directions can lead to instability or crashes. Regularly inspect and maintain ESCs to ensure they are functioning properly, looking out for signs of overheating or wear.

Understanding Brushless Motors and Propellers

Options for Brushless Motors: 1804 2300-2400KV vs 1306 3100KV

Choosing the right brushless motors is another vital decision in your drone build. The 1804 2300-2400KV motors provide a good balance between power and efficiency, suitable for lightweight builds. Alternatively, the 1306 3100KV motors offer higher speeds and are ideal for racing drones or more aggressive flying. Consider your intended use and balance weight, power, and efficiency when selecting your motors.

Setting up Carbon Fiber 5030 Propellers

Propellers are the drone’s driving force, and opting for Carbon Fiber 5030 propellers enhances performance due to their lightweight and durable nature. These propellers offer a good balance between thrust and efficiency. When installing, ensure that the propellers are properly secured and balanced to prevent vibrations that could affect flight stability.

Balancing weight and quality in motor selection

When selecting motors and propellers, it’s crucial to balance weight with performance. Heavier motors may offer more power but can push the drone’s weight over 250g if not carefully managed. Ensuring propellers are of high quality and properly balanced will contribute to a smoother flight and reduced wear on other components.

Receiver Installation: Ensuring Reliable Control

Types of receivers: Spektrum compatible DSM2 or DSMX Satellite Receiver

For reliable control, choosing the right receiver is important. Spektrum compatible DSM2 or DSMX Satellite Receivers are recommended for their robustness and compatibility with a wide range of radio transmitters. These receivers are compact and lightweight, fitting well into a variety of drone builds.

Steps for secure installation

To ensure secure installation, position the receiver where it won’t obstruct other components or interfere with moving parts. Use foam padding or zip ties to secure the receiver, reducing the risk of vibration damage. After installation, bind the receiver to your transmitter, following manufacturer instructions to ensure a stable connection.

Testing for optimal performance

Once installed, thorough testing of the receiver is essential for optimal performance. Perform range tests to ensure the receiver maintains a strong connection at your maximum flight distance. This will help prevent loss of control mid-flight and ensure a safe flying experience.

Weight Management: Tips for a Sub-250g Build

Significance of lightweight components

Building a drone under 250g is crucial for avoiding FAA registration and restrictions. Every component choice contributes to weight, so opting for lightweight materials like carbon fiber and nylon is essential. Lighter drones not only sidestep regulatory requirements but also tend to be more agile and efficient in flight.

Benefits of using nylon screws and spacers

Nylon screws and spacers, while lightweight, do not compromise on strength or durability, making them excellent choices for drone construction. They reduce overall weight, aiding in achieving the sub-250g goal, and also help in minimizing vibrations, which can affect flight stability.

Avoiding FAA registration through weight compliance

By keeping your drone under 250g, you can avoid the complexities associated with FAA registration. This compliance not only saves you the time and expense but also provides peace of mind, allowing you to focus more on enjoying and refining your drone flying skills.

Soldering Tips and Techniques

Tools required for precision soldering

Precision soldering is crucial in drone building, ensuring all connections are secure and reliable. Essential tools include a high-quality soldering iron, fine-tip soldering wire, and helping hands or a soldering station for stability. These tools aid in making precise connections, reducing the risk of short circuits.

Avoiding common mistakes

Common soldering mistakes include holding the soldering iron on the joint for too long, which can damage components, or insufficient solder, leading to weak connections. Practice on spare wires to build confidence, and always double-check connections to avoid potential issues.

Emphasis on testing and fitting before soldering

Before committing to soldering, test fit components to ensure alignment and functionality. This helps avoid costly mistakes and ensures all parts work in harmony. Taking the time to plan and test can save much frustration and ensure a smoother build process.

Community Support and Resources

Engaging with Hak5 community for learning and troubleshooting

The Hak5 community is an invaluable resource offering support, advice, and camaraderie for drone builders. Engaging with fellow enthusiasts can provide insights into best practices, troubleshooting tips, and innovative ideas, enhancing your overall learning experience.

Exploring forums and online groups

Online forums and groups are treasure troves of information. Participating in discussions, asking questions, and sharing your experiences can enrich your understanding and provide solutions to challenges you may encounter during your drone building journey.

Utilizing community resources for optimization

Leveraging community resources such as tutorials, user-generated guides, and shared experiences can optimize your drone’s performance. These resources can offer new perspectives and techniques, helping you refine your skills and achieve better results in your builds.

Conclusion: The Journey of Building a Drone

Summary of power system assembly process

The process of assembling a drone’s power system is both rewarding and educational. It involves selecting the right components, ensuring they work harmoniously, and understanding how each part contributes to the drone’s performance. Mastery of this phase is crucial for any successful drone build.

Highlighting the importance of preparation and planning

Proper preparation and planning are the bedrock of a successful drone building project. By choosing the right components, carefully assembling them, and rigorously testing each system, you lay the foundation for a drone that performs reliably and efficiently.

Encouragement for continuous learning and experimentation

The world of drone building is vast and ever-evolving, offering endless opportunities for learning and experimentation. Embrace this journey with curiosity and a willingness to explore new avenues, and you’ll find it a rewarding, exciting hobby that combines creativity with technology. By continuously expanding your knowledge, you’ll be well-equipped to tackle more complex projects and innovations in the future.